Quick Links

Table Of Content

Cross laminated timber panels present an incredible opportunity for architects and builders to combine timeless style, sustainable production, and innovative materials into durable, light, and unique architectural projects. CLT panels are one of the major types of mass timber – wood processed for greater structural strength and diverse applications.

The benefits of laminated wood panels are many, including aesthetic appeal, architectural versatility, project efficiency, and sustainability. Whether you’re designing a luxurious residential building, or a multifamily structure with many stories, mass timber solutions will enhance the design and appeal of the structure.

In this guide, we’ll examine the unique strengths of mass timber, differentiate between two main product types, explain several code considerations, and highlight cutting-edge manufacturers who can supply you with high quality materials for your next project.

Major Types of Mass Timber

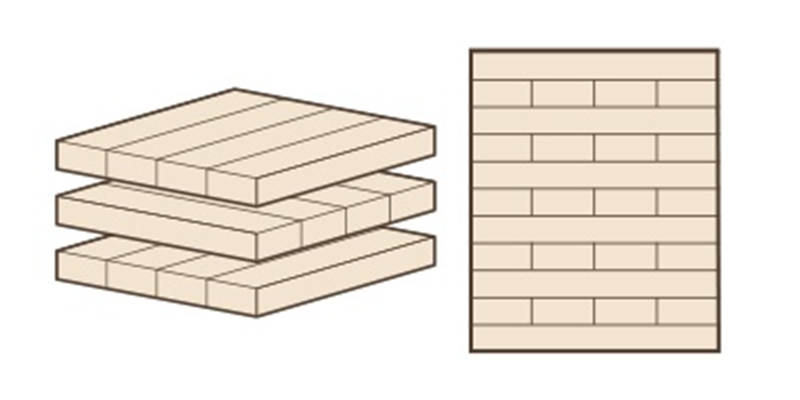

CLT panels are formed by stacking and gluing together multiple layers of lumber at alternating 90 degree orientations. These layers are then compressed under high pressure to create durable laminated wood panels.

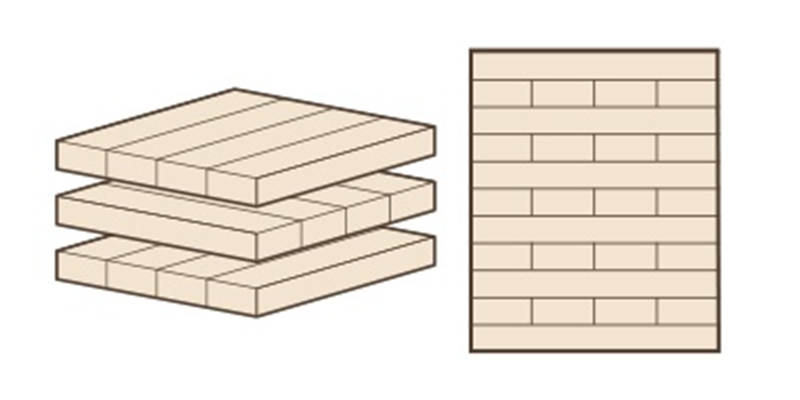

Glulam or GLT is formed by gluing together layers of timber with the grains lying parallel to one another. GLT is often used for beams and columns due to its high structural strength.

Image Credit: Hyne

Mass Timber Manufacturers

There are some innovative mass timber manufactures producing at the national level, such as Sterling Structural and Timberlab. Other great companies include Western Wood Structures, Nordic Structures, and Freres Lumber.

Depending on your location and project needs, these companies may be a great fit for your next build. We’ll explore some additional options below.

Featured Brand

SmartLam North America

Dothan, Alabama

SmartLam manufacturers versatile mass timber products from sustainably sourced Southern Yellow Pine, including cross laminated timber and glulam. Wood products can be manufactured to each design specification.

- Floor, roof, wall, and elevator smartshaft systems with high strength to weight ratio

- Pre-cut openings for doors, windows, mechanical apertures, and rake and plumb cuts increase on-site installation efficiency

- Cantilevers, projections, dramatic overhangs and more are all possible with high performance thermal and acoustical systems roof systems.

Featured Brand

Kalesnikoff

Castlegar, CanadaKalesnikoff manufactures efficient, responsible and safe CLT panels, Glue-Laminated Timber panels, and Glulam beams for various structural applications.

- Prefabricated modular mass timber options for increased efficiency on builds

- Quality, fine-grained wood sourced from slow growth of forests of Canada’s West Kootenay mountains

- Company initiatives and programs invest positively in employees, local community and causes, and environmental health, including reforestation.

Featured Brand

Mercer Mass Timber

Vancouver, CanadaMercer Mass Timber produces cross laminated timber, glue laminated timber, and long length finger joint products with enhanced fire resistance, improved acoustic properties, and greater architectural versatility than heavy timber products.

- Standardized beam, panel, post, and frame components can be assembled quickly into various configurations

- Spruce-Pine-Fir, Douglas Fir-Larch, and Southern Yellow Pine sourced from suppliers certified by LEED, the Sustainable Forestry Initiative, and more

Featured Brand

Rosboro

Eugene, OregonRosboro produces high quality glulam beams from Douglas Fir and Alaskan Yellow Cedar, finished to an architectural appearance, and engineered with true modulus of elasticity.

- They are installed as a single piece and span further than other stock glulam.

- Features: fire retardant treated, rim applications, integration with conventional framing systems, decking, continuous columns

- Custom glulam specifications with a variety of color and grain patterns and finishes

Featured Brand

DR Johnson Wood Innovations

Riddle, OregonFor over 50 years, DR Johnson Wood Innovations has specialized in the manufacture of glue-laminated beams from Douglas fir and Alaskan yellow cedar, engineered to meet specific customers’ needs.

- Incorporates the best available lamination stock for increased strength and durability, especially when installed with CLT panels.

- Design team utilizes 3D model interfaces to lay out each panel or beam requiring fabrication for your project

Become a Built for Home member.

It’s free and the best way to discover manufacturers with unique products that help you confidently deliver exceptional projects.

"*" indicates required fields